Piping

Wherever and whenever required

The well-equipped piping facility of Niron Staal has the flexibility to take on any type of piping or construction project. Require high-tensile steel grade piping? No problem, Niron is there for you. Our in-house welders are specialised in all steel welding techniques as well as the welding of aluminium, CuNiFer and stainless steel. Hence the ability to take on any specification or project.

Started in 2015 as an additional specialism to complement the line of existing services provided within Niron Staal, piping has now outgrown itself and operates as a stand-alone department. Naturally cross-channel projects with use of machining, steel construction and piping can be handled from one location, the Niron Staal premises, and are managed by one single point of contact.

As Niron Staal is located on the premises of Damen Shiprepair Amsterdam we are able to use their available resources such as the four graven drydocks, load-out quays, berths and crane assistance.

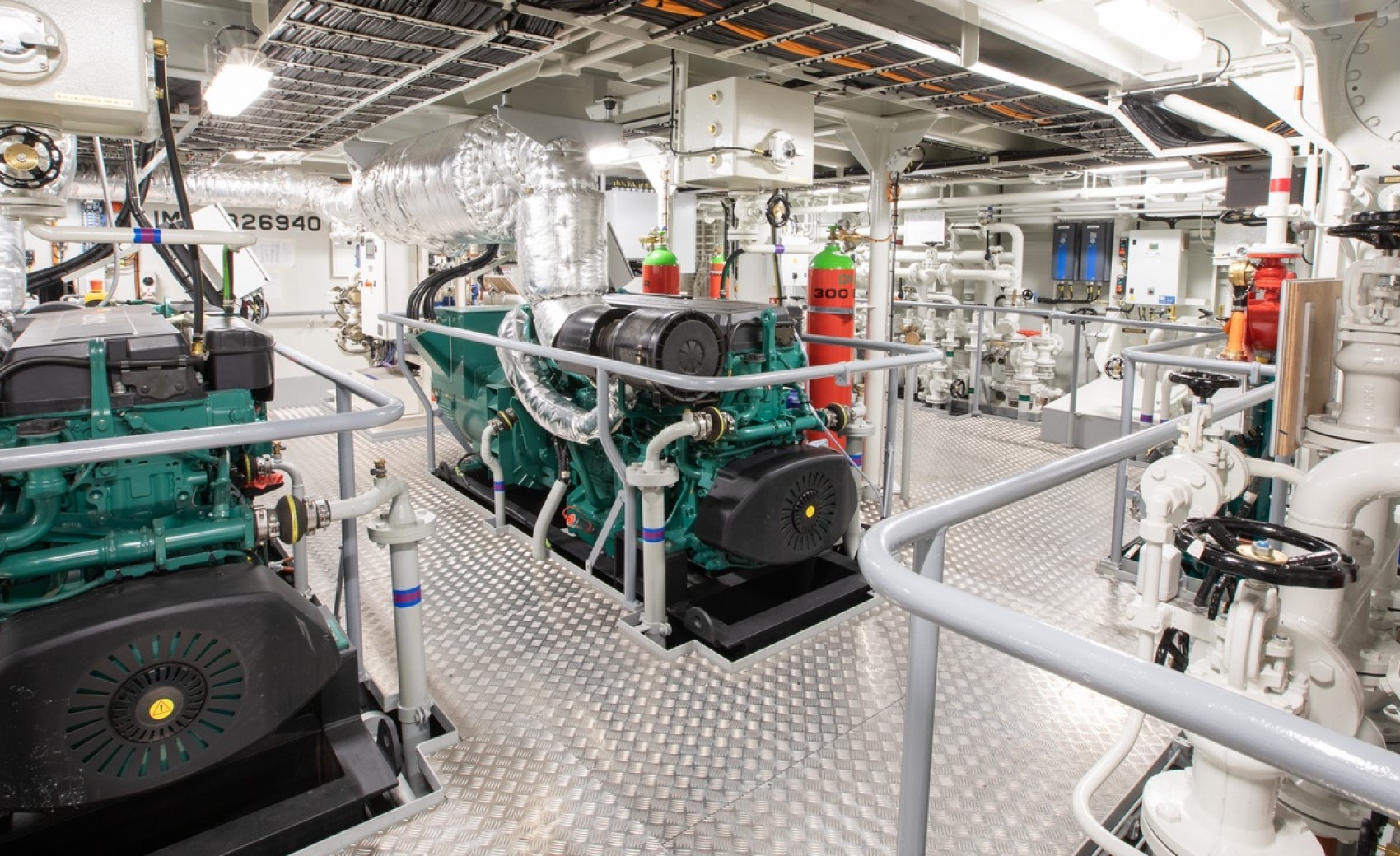

In-house prefabrication and on-site installation

With the facility being flexible and our welders being specialized in any type of welding techniques we are able to prefabricate all sorts of piping and (re-)install them on-site, wherever that may be. The complete system will be prefabricated in our workshop, placed on transport to the desired location, whereas that be onboard a vessel, onshore or offshore, and installed on-site by our own team of dedicated pipefitters or in collaboration with our colleagues from Damen Shiprepair Harbour & Voyage. Niron Staal guarantees a worldwide coverage for prefabrication of piping systems.

Piping constructions

Piping comes in many sort and varieties, repair of existing lines, fabrication of new to be installed systems or piping constructions. Over the last years Niron Staal has gained the knowledge and know-how in the fabrication and installation of piping systems such as Ballast Water Treatment Systems, fuel line upgrades, anti-heeling pipes, boat landing ladders and many more. Each system requires a different approach and technique but each time we aim for the highest quality possible.

Experience

It doesn’t matter if a pipe needs to be copied one on one, or will be fabricated from engineered isometric. There is specialized personnel for all ways of fabrication. If your project requires a tight time schedule we are able to scale up to two shifts and if needed even a third one. This means we are able to work 16 or 24 hours a day to meet your requirements.